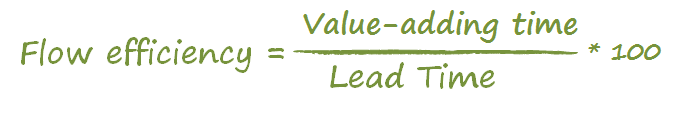

Efficiency is an indicator of how lean your organization is.

With respect to ITC companies:

- Flow efficiency of 2% has been reported [Zsolt Fabok, Lean Agile Scotland, Sep 2012]

- Efficiency between 5% and 15% is considered normal

- Efficiency > 40% is good!

What causes the low efficiency?

As well explained in This is Lean, there are three main sources of low efficiency:

Long Lead time

Waiting too long for a product or service generates additional needs for the customer that also need to be addressed and usually cause additional delays.

To give an example: the longer a customer waits for the solicited application or service, the higher the probability to ask for changes or even cancel the order. In addition, managing changes increases the delivery time (Lead time) even more.

Hence

Agile teams are more efficient because they use short time iterations.

Decreasing delivery time is one of the means to increase efficiency.

A manner of decreasing delivery time is reducing the size of the work items and the batches. Therefore, when I see requirements of 500-1000 person-hours each, and iterations of 3+ months, I always recommend reducing both the requirement size and the iteration duration.

Reducing the requirements size increases efficiency.

Too many work items in process

Working on too many items in parallel

- Requires additional effort, time and resource to manage them: know what was done in each one of them, where it is stored, what is pending, etc.

- Leads to multitasking, which is another main source of inefficiency. Here you can see a good summary of high cost of multitasking.

- Hides problems because when there are many open work items, it is difficult to spot and fix well quality problems.

- Causes anxiety and stress which reduces the quality of the work, increases problem-fixing time and hence reduces efficiency.

Therefore,

Reducing the work in progress in a kanban system increases workflow efficiency.

Too many handovers

Remember how you feel when you call, for instance, your mobilephone provider and you are transferred from an operator to an operator and each time you have to explain your problem from the very beginning. From customer perspectives many handovers generate frustration.

From service provider perspective handing over a work item to another person always carries the risks of losing information and generating defects. In addition any work transfer requires additional effort and time for explaining, orally or in written form, the current status of the job and what has to be taken into consideration in the subsequent steps.

Handovers cannot always be avoided however working in

multidisciplinary teams reduces their negative effects.