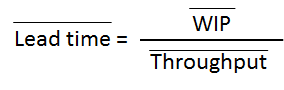

The origin of Little’s Law is the Queuing Theory and it is perhaps best known law in the IT systems performance modeling.

The law shows the relationship between Lead Time, Work in progress (WIP) and Throughput.

- Lead time: The period between the entry of a request in the system and the receipt of the request. It is measured by the elapsed time (minutes, hours, etc). The request may be a requirement, a user story, an incidence, material, a request from a user, etc..

- Work in process (WIP): the number of requests (work units) that are being processed, i.e. they have entered the system, but have not got out yet

- Throughput: the number of work units leaving the system at a given time, e.g. 3 user stories per day.

The conclusions of this law are equally interesting and important:

- The larger the WIP, the longer the lead time, i.e.the more it takes to finish the job started . In other words, to meet development or service deadline, we must reduce the work in process, or finish it before starting a new jobs. However, in lots of cases exactly the opposite happens: the teams start working on lots of tasks so that the whole project “goes” faster. Another reason for which one wants to ensure a lot of ongoing work is to achieve high resources utilization.Whatever the reason, assuming that the Throughput does not change, the increase of work in process also increases the time required for its completion (the Lead time).

Although it may seem counterintuitive, remember that reducing WIP helps meet SLA and reduce development Lead time.

- Focusing on reducing Lead time helps identifying obsolete activities that are carried out . Eliminating them has two positive effects: (1 ) eliminates waste in processes, and ( 2) reduces total WIP, which leads to shorter Lead time and a more efficient development .

- The higher the Throughput, the shorter the Lead timeThere are different ways to improve performance: automating value-adding activities (automating non-value-adding activities is equivalent to automating waste production), improving processes or adding more resources. If you decide to add more resources, observe the overall lead time because the additional resources add more work in progress as well.

- Each Lean initiative seeks to minimize waste and shorten production cycle. Reducing the production cycle is equivalent to reducing the Lead time. Minimizing waste includes an analysis of current inventory and the steps to reduce it. This is equivalent to reducing WIP.

Why is this law important for Project Managers?

- Little’s law is a tool to know the real performance of a software development team or an operations one

- Provides predictability

E.g. if we have to implement 50 requirements and the average team capacity is 5 requirements per week, the time that we will need is

50 requirements / 5 requirements per week = 10 weeks. - Shows that the larger the work batch, the longer the processing time, the Lead time

- Explains why multi-tasking delays instead of accelerating work completion.

Usually people believe that working on multiple tasks in parallel increases productivity. Therefore, assigning several tasks to a person is a common practice in the companies. However, unlike the machines, people are not so good in the execution of parallel processes. Increasing work in process also increases the time to change and re-start a task and therefore reduces throughput. As a result, the time to execute the work gets insufficient, and the started but not finished job begins to accumulate.

In short, Little’s law helps finding the balance between the work in progress and Lead time. - Provides the foundation to reaching optimal WIP limits. If WIP limits are below the optimal level, there are underutilized resources and performance is low. If the WIP limits exceed the optimal level, then work units start piling up in queues and this also reduces performance.

- Helps understand the effects of blocking a job or having to fix errors on project or service deadlines. In both cases it reduces Throughput and hence increases the Lead time.

Important conditions for applying Little’s Law:

Little’s law is very useful, however in addition to knowing the formula you have to take into account the conditions that have to be met for the law serves you:

- Use average values for all parameters: average lead time, average WIP and average throughput

- Units must be consistent, i.e., if we measure throughout in a week, the lead time also has to be a week, as well as the average WIP

- The system has to be stable, i.e. all the work that enters the system, has to go out of it; the total WIP at the beginning and at the end of the period has to be constant, the average arrival rate of work has to be equal to the average departure rate of work.

To summarize, the correct use of Little’s law helps achieve a smooth and steady workflow, and improves the predictability of projects and IT services. Work in process (WIP) is a key factor for project performance and the time to complete a software development or a service. Limiting WIP reduces Lead time and, in addition, leads to reducing waste in the workflow.

Related posts:

- The Project Management Principles that (Almost) Nobody Teaches

- Bottleneck Law

- The effects of the variation

- Esteban, the “bottleneck” (a real case)

References

- Little’s Law on wikipedia

- Little’s Law – an article in .pdf format